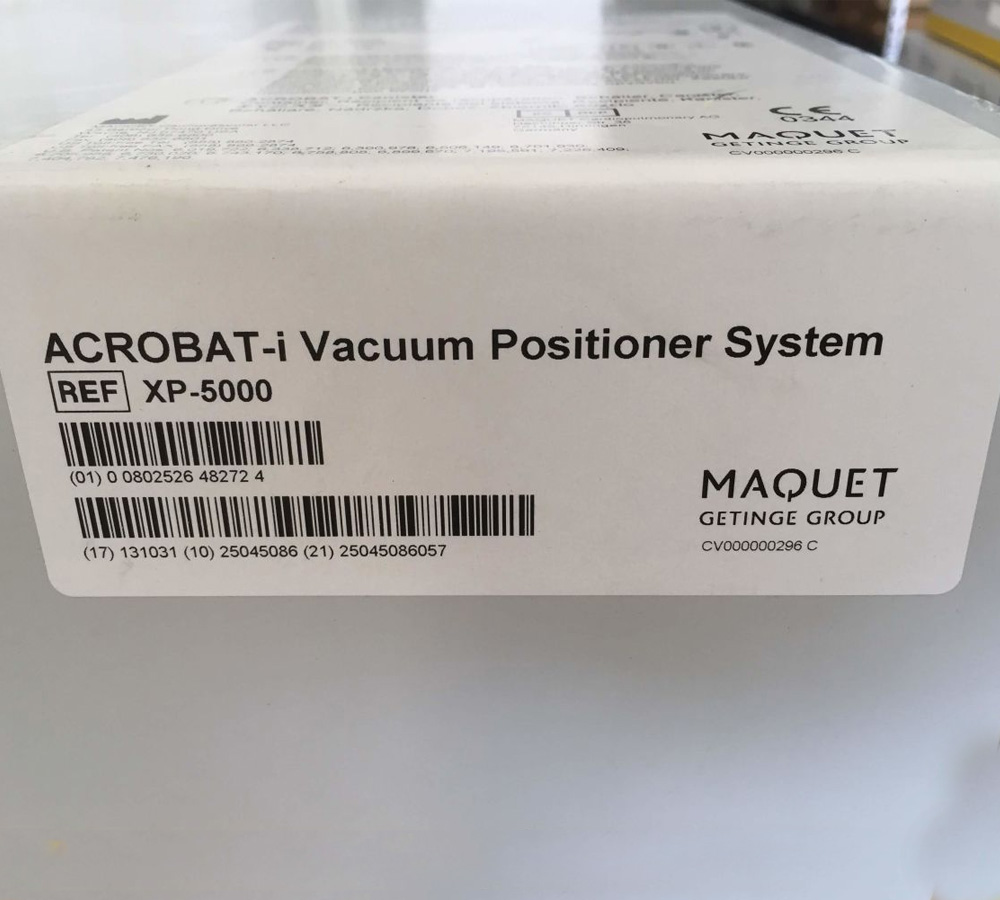

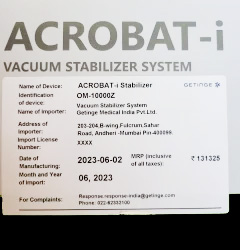

Acrobat I Vacuum Stabilizer System

Acrobat I Vacuum Stabilizer System

The ACROBAT I Vacuum Stabilizer System is an advanced medical device designed to enhance precision during cardiac surgeries. Utilizing innovative vacuum technology, this system provides exceptional stabilization and positioning of the heart, crucial for performing complex procedures like off-pump coronary artery bypass grafting (OPCABG). The ACROBAT I is known for its user-friendly design, reliable performance, and compatibility with a range of surgical instruments, making it an invaluable tool in reducing patient recovery times and improving surgical outcomes.

For healthcare professionals seeking to purchase the ACROBAT I Vacuum Stabilizer System, Satya Sales offers this high-quality product along with a comprehensive range of cardiovascular solutions. Satya Sales is a trusted supplier known for providing top-notch medical devices and ensuring excellent customer support. Purchase the ACROBAT I Vacuum Stabilizer System from Satya Sales to equip your surgical team with state-of-the-art technology and enhance patient care.

Supplier of

Acrobat i vacuum stabilizer system

The The ACROBAT I Vacuum Stabilizer System is a specialized piece of equipment designed to enhance the efficiency and safety of vacuum processes. It is commonly used in various industrial and scientific applications where precise control of vacuum pressure is crucial. Here are the key .

Acrobat i vacuum stabilizer system with special price available for Bulk orders

Acrobat i vacuum stabilizer system Features

Precision Control : The system offers highly accurate control of vacuum pressure, which is essential for processes requiring specific pressure conditions.

Stabilization : It stabilizes the vacuum environment, reducing fluctuations that can affect the quality and consistency of the processes.

User-Friendly Interface: Typically includes an intuitive interface for easy monitoring and adjustment of settings.

Compatibility: Designed to integrate seamlessly with existing vacuum systems and equipment.

Safety Mechanisms: Equipped with safety features to protect both the equipment and the user, such as overpressure protection and automatic shutoff.

Acrobat i vacuum stabilizer system Benefits

Improved Process Efficiency: By maintaining stable vacuum conditions, the system can improve the efficiency and reliability of vacuum-dependent processes.

Enhanced Product Quality: Consistent vacuum pressure helps in achieving higher quality and uniformity in products.

Reduced Downtime: Automation and precise control reduce the need for manual intervention and minimize downtime due to pressure fluctuations.

Versatility: Suitable for a wide range of applications, including research laboratories, manufacturing, and other industrial processes.

Cost-Effective: Over time, the efficiency and reliability improvements can lead to significant cost savings.

Acrobat i vacuum stabilizer system Application

Research Laboratories: Used in experiments and tests that require precise vacuum conditions.

Manufacturing: Essential for processes like coating, drying, and degassing where vacuum stability is crucial.

Pharmaceuticals: Used in the production of drugs and other medical products where contamination-free environments are necessary.

Semiconductor Industry: Critical for processes such as semiconductor fabrication and other electronics manufacturing..

Overall, the ACROBAT I Vacuum Stabilizer System is a vital tool for any industry or field that relies on stable and precise vacuum conditions..

Why Choose Satya Sales?

Satya Sales Cardio Vascular Products and Devices seller is best suitable choice for purchasing the ACROBAT I Vacuum Stabilizer System for several reasons.

Specialization: Satya Sales Cardio Vascular Products and Devices seller specializes in cardiovascular products and devices. While the ACROBAT I Vacuum Stabilizer System is not directly related to cardiovascular health, their specialization suggests a focus on precision and reliability in medical equipment, which could extend to other types of technical equipment like vacuum stabilizers.

Quality Assurance: Given their focus on medical devices, Satya Sales Cardio Vascular Products and Devices seller likely adheres to strict quality standards and regulations. This could translate into ensuring that the ACROBAT I Vacuum Stabilizer System they provide meets high-quality benchmarks, offering reliability and performance.

Expertise:

Their experience in the medical device industry may mean they have knowledgeable staff who can provide guidance and support regarding the selection, installation, and use of the ACROBAT I Vacuum Stabilizer System. This expertise can be invaluable, especially for complex equipment like vacuum stabilizers.

Service and Support:Satya Sales Cardio Vascular Products and Devices seller may offer excellent customer service and support, including maintenance, troubleshooting, and after-sales assistance. This can be crucial for ensuring the proper functioning and longevity of the vacuum stabilizer.

Potential Cost Savings: While the initial cost of the ACROBAT I Vacuum Stabilizer System is a consideration, purchasing from a specialized seller like Satya Sales Cardio Vascular Products and Devices may offer competitive pricing or bundled deals that could result in cost savings over the long term.

One-Stop Shop:If you have other cardiovascular or medical equipment needs, purchasing from a seller like Satya Sales Cardio Vascular Products and Devices could offer the convenience of sourcing multiple items from a single supplier, streamlining procurement processes.

WHY SHOULD WE

Buy ACROBAT I

Vacuum Stabilizer System

Buy Acrobat i vacuum stabilizer system from Satya Sales reputed dealer of cardiac surgery products.

The ACROBAT I Vacuum Stabilizer System offers numerous benefits that can significantly enhance the efficiency, quality, and safety of vacuum-dependent processes. Its precision control, reliability, and advanced features make it a valuable investment for businesses and research institutions seeking to optimize their operations and achieve better outcomes.